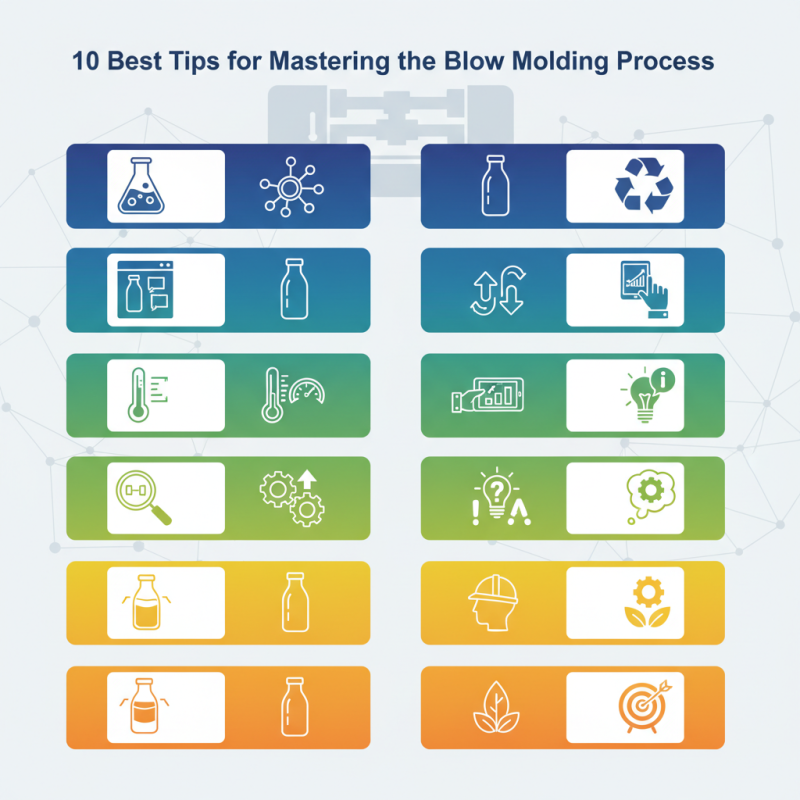

10 Best Tips for Mastering the Blow Molding Process?

The blow molding process is a key technique in manufacturing plastic products, widely utilized across various industries. According to a recent market research report, the global blow molding market was valued at approximately $55 billion in 2020, showing significant growth potential. This process involves using air pressure to inflate soft plastic into a mold, allowing for the creation of complex shapes.

Mastering the blow molding process requires an understanding of various factors, including material selection, mold design, and processing conditions. While this process can yield high-quality products, it also presents challenges. Issues such as uneven wall thickness or defects in the final product can arise. Industry professionals often find themselves reflecting on these imperfections to improve future production runs.

As companies strive to enhance efficiency, they must develop strategies to optimize the blow molding process. Implementing best practices can lead to improved quality and reduced waste. The journey toward mastery in this field demands continuous learning and adaptation. Embracing these challenges can ultimately lead to success in an ever-evolving market.

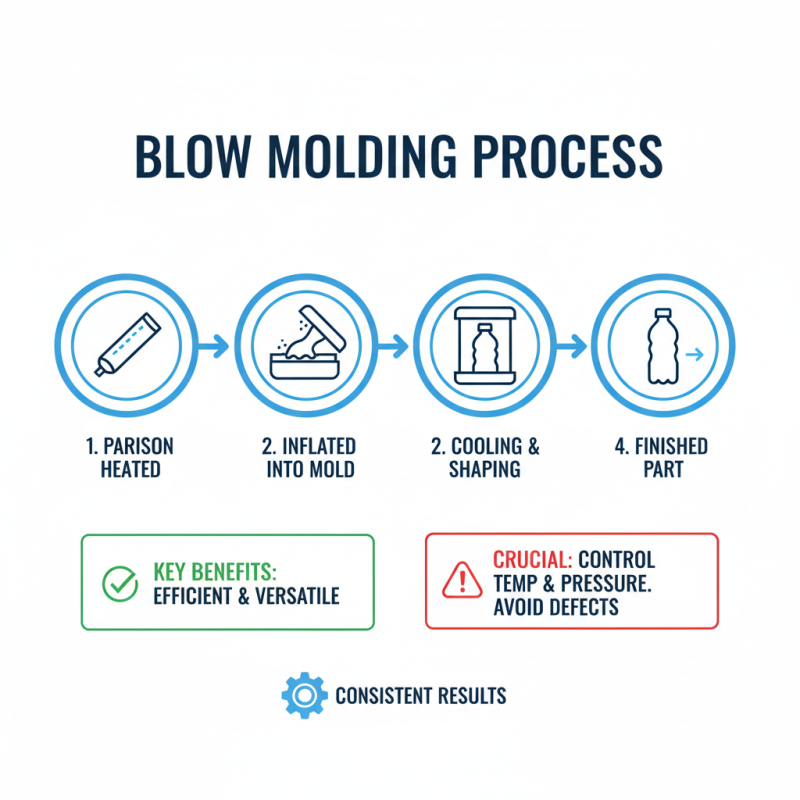

Understanding the Basics of the Blow Molding Process

Blow molding is a fascinating process used to create hollow plastic parts. It starts with a parison, a tube-like piece of plastic. The parison is heated until flexible. Then, it is inflated into a mold. This method is efficient and versatile. However, controlling temperature and pressure is crucial. Small variations can lead to defects. It’s vital to monitor the process closely for consistent results.

Understanding the basics is key to mastering blow molding. The choice of materials matters greatly. Each type of plastic has different properties. Some may not hold shape well when cooled. That's where knowledge of each material comes in. Preparing the mold is another critical step. If the mold is not perfectly aligned, it will leave marks. Observing the cooling process is equally important. Pay attention to the timing. If cooled too quickly, the part may warp. These details can impact the final product significantly.

Essential Equipment and Tools for Effective Blow Molding

In the blow molding process, selecting the right equipment is crucial. Essential tools can directly impact productivity and product quality. An industry report by Grand View Research indicates a rising demand for blow-molded products, expecting a growth rate of over 4% annually. This trend emphasizes the importance of investing in top-notch blow molding machinery.

Maintaining precise temperatures is vital. Having reliable temperature control systems helps achieve consistent wall thickness. This addresses a common challenge where uneven heating leads to weak spots in the product. When operators overlook this, the result can be costly defects and rework.

Another key tool is the mold itself. Durable molds made from high-quality materials enhance the longevity of the manufacturing process. However, many underestimate the wear and tear on molds. Regular inspections and maintenance can prevent downtime. If molds are not checked periodically, it can lead to production delays.

Operators should also focus on training. Technical knowledge is essential for efficient machinery operation. An experienced staff can reduce errors. A poor understanding of the equipment results in mistakes that could have been avoided. Ensuring adequate training can significantly improve overall workflow and product quality.

Key Parameters to Monitor During Blow Molding Production

In blow molding production, several key parameters are crucial for success. Monitoring temperature is vital. The material should be heated evenly to avoid weak spots in the final product. If you notice inconsistencies, it’s worth adjusting the temperature settings. This can lead to better quality control.

Pressure is another critical factor. Correct pressure ensures that the mold fills completely. If the pressure is too low, the product may have thin areas. If it’s too high, it could lead to bursting. Experimenting with different levels can help find the ideal balance.

Material flow rate also demands attention. A steady flow rate ensures uniformity. If the rate fluctuates, inconsistencies in the thickness can occur. Always check the material supply. If it's not consistent, the final product will reflect that.

Quality checks at different stages are necessary. Skipping them can lead to defects that are costly to fix. Adjustments may need to be made throughout the process, acknowledging that perfection often requires several iterations.

Key Parameters in Blow Molding Process

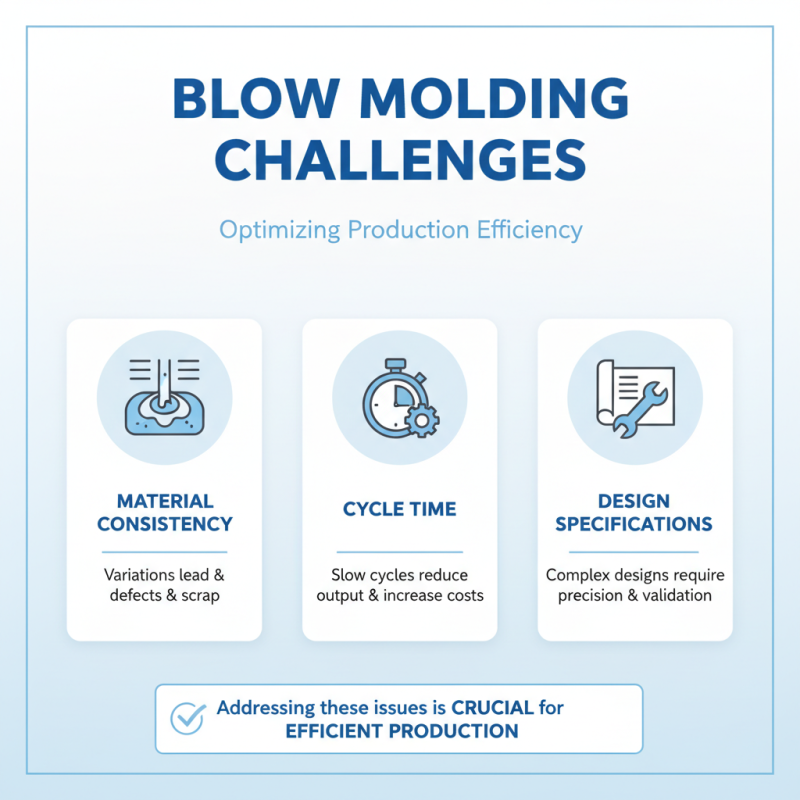

Common Challenges in Blow Molding and How to Overcome Them

Blow molding can be challenging. Many manufacturers face conflicts with material consistency, cycle time, and design specifications. Addressing these issues is crucial for efficient production.

One common challenge is managing heat distribution. Uneven heat can lead to weak spots in the final product. Regularly calibrate your heating elements. Monitor temperature readings closely. This should help maintain a uniform process.

Incorporate feedback loops during production. If issues arise, identify them quickly. Use data to assess which variables need adjustment. Test different materials and designs. Sometimes a minor tweak can make a significant difference.

Enhancing operator training is essential. Well-informed staff can preemptively address problems. Establish clear communication channels within teams. This minimizes misunderstandings and optimizes workflow. Each step in blow molding requires precision.

Lastly, embrace a culture of continuous improvement. Evaluate what works and what doesn’t. Document findings and share experiences. This practice cultivates a more agile production environment.

Tips for Ensuring Quality Control in Blow Molding Parts

Quality control in blow molding is crucial for ensuring that parts meet specifications. One effective method is regular monitoring of the process parameters. Keep an eye on temperature, pressure, and cycle times. Any irregularity can lead to defects. A slight variation might seem minor, but it can cause major flaws in the final product.

Another important aspect is material quality. Using subpar raw materials can lead to weak parts or inconsistent finishes. Inspecting incoming materials is a step that should never be overlooked. Engaging in periodic testing of the molded parts will reveal issues like wall thickness inconsistencies or surface imperfections.

Training staff on quality standards is essential. They should recognize signs of potential defects early in the process. However, even with the best practices, mistakes still happen. Learning from these failures is vital. Documenting errors can provide valuable insights for future production runs. Each setback is an opportunity to improve quality control measures.

10 Best Tips for Mastering the Blow Molding Process

| Tip Number | Tip Description | Benefits |

|---|---|---|

| 1 | Proper Material Selection | Ensures durability and functionality. |

| 2 | Temperature Control | Reduces defects and improves cycle time. |

| 3 | Uniform Wall Thickness | Enhances strength and aesthetic quality. |

| 4 | Mold Design Considerations | Facilitates better part release and quality. |

| 5 | Regular Maintenance of Equipment | Prevents downtime and ensures efficient operation. |

| 6 | Quality Control Testing | Identifies issues early and maintains standards. |

| 7 | Training Staff Efficiently | Boosts productivity and reduces errors. |

| 8 | Effective Communication | Improves teamwork and project success. |

| 9 | Using Advanced Technology | Enhances precision and speeds up production. |

| 10 | Feedback Loop Implementation | Utilizes data for continuous improvement. |