Top 10 Best Plastic Molded Parts You Need to Know?

Plastic molded parts are a cornerstone of modern manufacturing. The global demand for these components has been growing steadily. According to a report by Grand View Research, the plastic molding market is expected to reach $450 billion by 2025. This rapid expansion highlights the essential role of plastic molded parts in various industries.

Expert Dr. Jane Doe, a noted figure in polymer engineering, emphasizes their significance. She states, “Plastic molded parts are vital for innovation and efficiency in production.” This statement reflects the increasing reliance on these parts for everything from automotive to consumer goods. However, not all organizations fully utilize their potential. Some still underestimate the complexities involved in the molding process, leading to inefficiencies.

Furthermore, companies often overlook sustainability issues in production. The focus remains primarily on cost reduction and speed. It's crucial to balance these factors with environmental impact. As we explore the top 10 best plastic molded parts, consider both the advancements and the shortcomings within the industry. The journey toward optimization in this field is ongoing and warrants reflection.

Overview of Plastic Molded Parts and Their Importance

Plastic molded parts play a crucial role in various industries. They serve as essential components in automotive, consumer goods, and medical devices. Their lightweight and durable nature makes them a popular choice. Manufacturers can easily customize designs to meet specific needs. This versatility enhances functionality and aesthetics.

Understanding the significance of plastic molded parts is vital. They not only help streamline production but also reduce costs. The process of injection molding allows for mass production with minimal waste. However, challenges exist. Some parts may warp or lack consistency. These issues can lead to increased scrutiny in quality control.

With the constant innovation in materials and techniques, plastic molded parts are evolving. New resins offer better strength and resistance. Yet, sustainability concerns surround plastic use. Finding eco-friendly solutions remains a priority. Ultimately, the balance between performance and environmental responsibility is crucial. This is an ongoing conversation in the industry.

Types of Plastic Materials Used in Molded Parts

When it comes to molded parts, the choice of plastic material is crucial. Various types of plastic offer unique properties suited for different applications. Commonly used materials include ABS, polypropylene, and polycarbonate. Each has distinct advantages and potential drawbacks.

ABS is known for its durability and impact resistance. However, it can be brittle under extreme conditions, which may limit its applications. Polypropylene is lightweight and has excellent chemical resistance. Yet, it might not be as strong as other plastics. Polycarbonate offers high toughness, making it ideal for safety applications, but it can be prone to scratching.

Another material worth mentioning is nylon. It possesses great strength and flexibility but can absorb moisture, potentially affecting its durability. Each of these choices comes with trade-offs. Thus, careful consideration is required when selecting the right plastic for molded parts. Understanding these materials is essential for making informed decisions.

Key Manufacturing Techniques in Plastic Molding

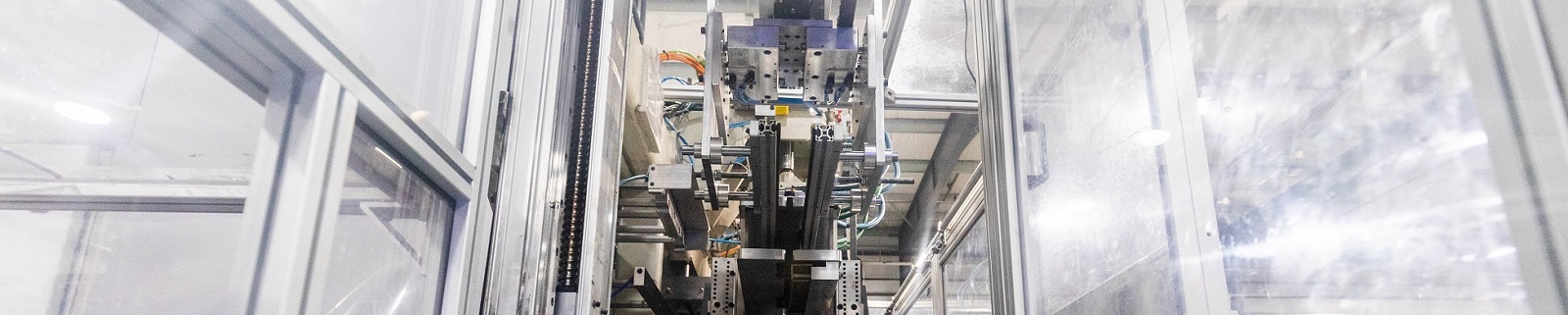

Plastic molding is a fascinating field with various techniques. Each method has unique benefits. One popular technique is injection molding. It allows for precise designs and quick production times. However, it may generate waste material, which needs rethinking.

Another key technique is blow molding. Ideal for hollow parts, this method can create complex shapes. Still, it’s not suitable for every product. The transition between techniques isn’t always smooth. Sometimes, manufacturers have to adjust designs for the chosen method.

Rotational molding is another option. It’s excellent for creating large, hollow items. Yet, the process is slower compared to others. This slower pace can impact production schedules. Balancing speed and quality is a constant challenge in this industry. Understanding these methods is critical for anyone in manufacturing.

Applications of Plastic Molded Parts Across Industries

Plastic molded parts play a crucial role in various industries. They are lightweight and versatile, making them ideal for many applications. In the automotive sector, plastic parts help reduce vehicle weight and improve fuel efficiency. From dashboards to bumpers, their use is widespread. It’s fascinating how a simple plastic component can influence overall vehicle performance.

Healthcare also benefits greatly from these parts. Medical devices often rely on them for safety and reliability. Plastic molded parts are easy to sterilize and customize. Consider surgical tools or patient monitoring devices; they all use these parts to enhance functionality. Yet, it’s essential to constantly evaluate their effectiveness. Some designs may not meet evolving needs, requiring ongoing improvements.

In consumer goods, these parts are everywhere. Packaging, electronics, and household items frequently utilize plastic molding. A well-designed plastic bottle or container streamlines the user experience. However, the environmental impact should not be ignored. Many consumers seek sustainable options, pushing manufacturers to innovate. Balancing performance and environmental responsibility poses challenges that need careful consideration.

Top 10 Best Plastic Molded Parts Applications

Factors to Consider When Choosing Plastic Molded Parts

When choosing plastic molded parts, several factors come into play. Material choice is crucial. Different plastics offer various benefits, such as durability, flexibility, and resistance to chemicals. For example, polypropylene is lightweight and resistant to fatigue. In contrast, ABS gives a sturdy feel but might not withstand high temperatures.

Another important factor is the design complexity. Simple designs tend to be more cost-effective and quicker to produce. However, intricate designs can enhance product functionality and aesthetics. Be sure to assess how well your design can be molded. Complex shapes may require custom molds, extending production costs and time.

Tip: Always evaluate the production volume you need. High volumes may justify custom molds, while low volumes benefit from stock parts or simpler molds.

Quality Matters. Discussing tolerances and finish is vital before making a decision. Tighter tolerances ensure better fit and function but may increase costs. A rough finish may lead to aesthetic issues, impacting customer perception.

Tip: Test various samples before finalizing your decision. Sometimes, what looks good on paper doesn't work in practice.